CONTENTS

PRINCIPLE

VISCOSITY

ALCAP- ALFA LAVAL

OPERATION OF PURIFIER

PURIFIER SEPARATION PROCESS

Liquid flow

Liquid seal in purification

Displacement of oil

Gravity disc

Clarifier disc

Sludge discharge mechanism

Bowl opening & closing

PRINCIPLE OF PURIFIER

The centrifuge includes parts that rotate at high speed. This means that:

•Kinetic energy is high

•Great forces are generated

•Stopping time is long

The Marine high-speed centrifugal separator is specifically designed for cleaning lubricating oils and low viscosity fuel oils from water and solid particles (sludge). The cleaned oil is discharged continuously, while the sludge is discharged at intervals.

VISCOSITY

The separator handles the following types of lubricating oils and low viscosity fuel oils:

•Distillate, viscosity 1,5 - 5,5 cSt/40 °C

•Marine diesel oil, viscosity 13 cSt/40 °C

•Intermediate fuel oil and heavy fuel oil (viscosity 30-380 cSt/50 °C)

•Lubricating oil of R & O type, detergent, or steam turbine.

Items that can be removed via the

purifier

Items that cannot be removed via the purifier

Vanadium, and SulphurALCAP- ALFA LAVAL

The separator can be operated either as a purifier or as a clarifier.

When operated as a purifier the separator discharges the separated water continuously.

When the oil contains only small amounts of water the separator is operated as a clarifier, discharging the water with the solid particles.

The separator has to be installed together with devices to control it.

OPERATION OF PURIFIER

|

| purifier sectional view |

The separator Bowl (C) is driven by an electric motor(A) via a flat-belt power transmission (D) and bowl spindle(B). The motor drive is equipped with a friction coupling to prevent overload.

The bowl is of disc type and hydraulically operated at sludge discharges. The hollow bowl spindle (B) features an impeller that pumps closing water from a built-in tank to the operating system for sludge discharge.

The main inlets and outlets are shown with their connection numbers in the illustration.

Outline of function

The separation process takes place in the rotating bowl. Un-separated oil is fed into the bowl through the inlet The oil is cleaned in the bowl and leaves the separator through the outlet via a paring chamber.

Impurities heavier than the oil are collected in the sludge space at the bowl periphery and removed automatically at regular intervals.

PURIFIER SEPARATION PROCESS

Liquid flow

|

| purifier Liquid flow |

Separation takes place in the separator bowl to which unseparated oil is fed through the inlet pipe (201). The oil is led by the distributor (T) towards the periphery of the bowl.

When the unseparated oil reaches the slots of the distributor, it will rise through the channels formed by the disc stack (G) where it is evenly distributed into the disc stack.

The oil is continuously separated from water and sludge as it will flow toward the center of the bowl. When the cleaned oil leaves the disc stack it rises upwards and enters the paring chamber. From there it is pumped by the paring disc (F) and leaves the bowl through the outlet (220).

Separated sludge and water move towards the bowl periphery. In purification separated water rises along the outside of the disc stack, passes from the top disc channels over the edge of the gravity disc (K), and leaves the bowl into the common sludge and water outlet (221) of the separator.

Heavier impurities are collected in the sludge space (H) outside the disc stack and are discharged at intervals through the sludge ports (L).

Process Water

Water that enters the purifier or separator through a valve on top of the apparatus and is used for filling the bowl first and thus obtaining a seal and interface for purification of oil.

Operating Water

1)Water which

opens and closes the sliding bowl,

2) It enters the separator through

the paring disc at the bottom of the bowl body,

3) It operates the slide mechanism

also to lower the bowl for desludging purposes

4) It again assists to close the bowl

and keeps it closed continuously during purification.

By applying a high pressure the

interface moves outward and with a low back pressure the opposite results,

therefore a constant pressure control valve is fitted at the clean oil outlet. It

is important to note that when an excessive amount of water is present in the

fuel the temperature for centrifuging must be kept below the boiling point of

water, otherwise foaming and agitation of the fuel takes place making it impossible to control. Under these circumstances, it will be necessary to purify at a

very low rate to realize a reasonable efficiency.

Liquid seal in purification

|

| Liquid seal in purification |

Displacement of oil

To avoid oil losses at sludge discharge, displacement water is fed to the bowl.

Prior to a discharge, the oil feed is stopped and displacement water is added through the water inlet (206). This water changes the balance in the bowl and the interface (X) moves inwards to a new position (Y), increasing the water volume in the sludge space. When the sludge discharge takes place sludge and water alone are discharged.

Sludge discharge occurs while the displacement water is still flowing. A new water seal will therefore be established immediately afterward. The oil feed is then turned on again.

Gravity disc

What is the use of a gravity disc?

The main component of the purifier is the correct size gravity disc or dam ring which is responsible for creating an interface between the oil and water. 2) Clarifier: When a centrifugal is arranged to remove only impurities and a small amount of water, it is called the clarifier.

In the purification mode, the position of the interface (X) can be adjusted by replacing the gravity disc (K) with one of a larger or smaller size.

A gravity disc of a larger size will move the interface towards the bowl periphery, whereas a disc of a smaller size will place it closer to the bowl center

Clarifier disc

In the clarification mode, the gravity disc is replaced by a clarifier disc which seals off the water outlet. In this case, no water seal is required and consequently, there is no oil/water interface in the bowl. The clarifier disc is an optional disc with a hole diameter of 40 mm. This disc is not shown in the nomograms.

Sludge discharge function

|

Sludge discharge mechanism |

Sludge is discharged through a number of ports (L) in the bowl wall. Between discharges, these ports are covered by the sliding bowl bottom (M), which forms an internal bottom in the separating space of the bowl. The sliding bowl bottom is pressed upwards against a sealing ring (m) by the force of the closing water underneath.

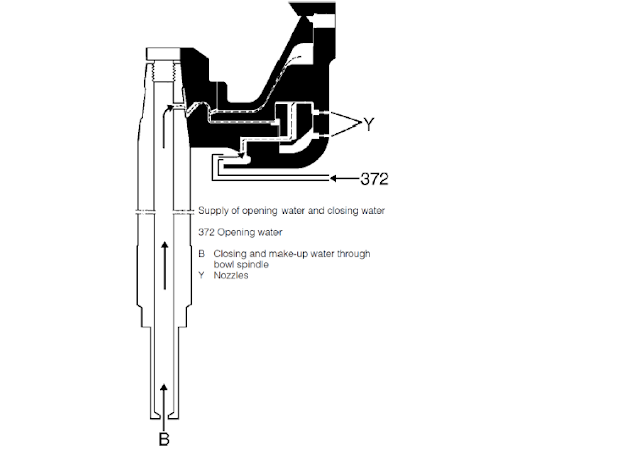

The sliding bowl bottom is operated hydraulically by means of operating water supplied to the discharge mechanism from an external freshwater line. Opening water is supplied directly to the operating system in the bowl while closing water is supplied to the built-in closing water tank, and pumped to the operating system through the bowl spindle.

The opening and closing only take a fraction of a second, therefore the discharge volume is limited to a certain percentage of the bowl volume. This action is achieved by the closing water filling space above the upper distributor ring and pushing the sliding bowl bottom upwards. Simultaneously, the water in the chamber below the operating slide is drained off through the nozzles in the bowl body.

Bowl opening

The key event to starting a sludge discharge is the downward movement of the operating slide. This is accomplished by the supply of opening water (372) to the discharge mechanism. Water is drained off through nozzles (Y) in the bowl body. The sliding bowl bottom is rapidly pressed downwards by the force from the liquid in the bowl, opening the sludge ports.

|

| opening closing |

Bowl closing

After the sludge is discharged the sliding bowl bottom is immediately pressed up and the sludge ports in the bowl wall are closed.

Needs to update more please write us at marinersight@gmail.com

If you want to to be on the best website, then it means you better read this

ReplyDeleteair purifier manufacturer

olansi air purifier

air purifier factory

Thanks for posting the useful information.

ReplyDeleteSiddhivinayak Enteprises iso 9001-2015 has over decade combined experience as manufacturer, exporter within the centrifuge industry dealing in Centrifuge Separators, Plate Heat Exchanger, Milk Processing Plant, Spare Parts In India

Ghee Clarifier manufacturer in pune

Pasteurizer Gaskets dealer in india

Dairy Equipment dealer in pune

Milk Processing Plant supplier in india

Plate Heat Exchanger Gaskets supplier in pune

Plate Heat Exchanger exporter in india

Electrical Farm Cream Separator manufacturer in india

Farm Cream Separator manufacturer in pune

Ghee Clarifier dealer in india

Edible Oil Centrifuge Separators dealer in pune

Marine Centrifuge Separators supplier in india

Heat Exchanger Plates supplier in pune

Centrifuge separators supplier in pune

Milk Processing Unit exporter in india

Nice post thanks for sharing.

ReplyDeleteGhee Clarifier manufacturer in india.we offers the best Ghee Clarifier manufacturer in pune.This is the perfect place for Ghee Clarifier supplier in india.click here to more information. Ghee Clarifier dealer in pune,Ghee Clarifier dealer in india,Ghee Clarifier supplier in pune, Ghee Clarifier exporter in india.

Ghee Clarifier manufacturer in pune

Ghee Clarifier manufacturer in india

Ghee Clarifier exporter in india

Ghee Clarifier supplier in pune

Ghee Clarifier supplier in india

Ghee Clarifier dealer in pune

Ghee Clarifier dealer in india

I will recommend anyone looking for Business loan to Le_Meridian they helped me with Four Million USD loan to startup my Quilting business and it's was fast When obtaining a loan from them it was surprising at how easy they were to work with. They can finance up to the amount of $500,000.000.00 (Five Hundred Million Dollars) in any region of the world as long as there 1.9% ROI can be guaranteed on the projects.The process was fast and secure. It was definitely a positive experience.Avoid scammers on here and contact Le_Meridian Funding Service On. lfdsloans@lemeridianfds.com / lfdsloans@outlook.com. WhatsApp...+ 19893943740. if you looking for business loan.

ReplyDelete“I could not have closed on my first home without Mr, Benjamin Lee ! Benjamin and his team went above and beyond for me on this transaction. He handled my very tight turn around time with ease and was always available for me when I had questions (and I had plenty), even when he was away from the office, which I greatly appreciated! He and his team handled many last-minute scrambles with the seller and worked tirelessly to make sure that I could close before my lease (and my down payment assistance, for that matter) expired. Mr Benjamin is incredibly knowledgeable Loan Officer, courteous, and patient. I went through a couple offers on properties before my final purchase and Benjamin was there to help with each one, often coordinating with my agent behind the scenes. I felt supported throughout the entire process. Thanks to Benjamin and the tireless efforts of his team, I am now a proud home owner! I would encourage you to consider Benjamin Briel Lee for any kind of loan.Mr, Benjamin Lee Contact informaions.via WhatsApp +1-989-394-3740 Email- lfdsloans@outlook.com.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteNice Article! We provide the best deals and offers on water purifiers in Mohali . We have water purifiers with advanced technology. We deal in best quality water purifiers at lowest prices.

ReplyDeleteThis blog post provides a clear and informative explanation about centrifugal separators.

ReplyDelete